of the rakes increased, to use it as a Side Air-lift type. No matter which type of Air-lift Agitator you have, it is the basis for any of the three general types, for each type has hollow revolving center shaft so that air can be added for Center Air-lift. A unit acquired originally for use as a Center Air-lift type, need only have the Side Air-lift pipes installed, the angle of the rakes changed and the R.P.M. Each type has its own advantages and application. Center Air-lift, Side Air-lift or combined Side and Center Air-lift.

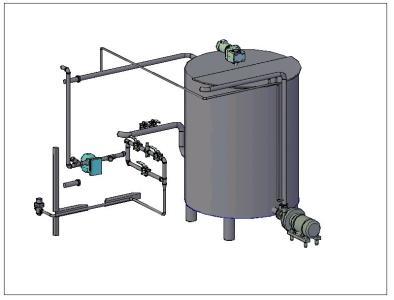

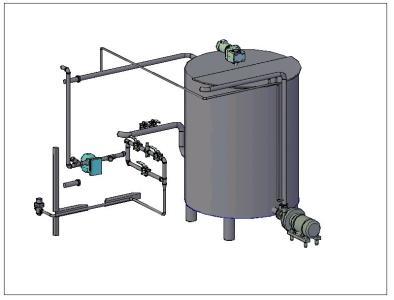

FLOTATION AGITATOR AND CONDITIONER (Open Type)Īny Air-lift Agitator is readily convertible from one to another of three general types. AGITATOR, (Open Gear Type) Center and Side Air-lift. Magnetic-driven agitators are also available where a hermetic seal is used in place of a mechanical seal. The number of impellers depends on the height of the liquid inside the vessel or tank.

The shaft of the agitator is connected to the motor and gearbox and the impeller rotates to perform mixing.

A motor with a gearbox option for speed control. A shaft with an impeller and impeller blades. Table 1: Comparison of different types of agitators Components of an AgitatorĪn agitator is usually composed of three main components. Can efficiently handle visco-elastic liquids. Propeller Agitators Can handle corrosive materials with a glass lining. High power and high-efficiency gearbox requirement. Not preferred for highly viscous solvents Anchor Agitators Widely used in the pharma industry. High radial flow, good for dispersion operation. Turbine Agitator Liquids and gas reactions, widely used for reaction and extraction operations. High power consumption, Inefficient mixing.

Type of Agitator Applications Advantages Disadvantages Paddle Agitator Mixing of Solids, Slurry Mixing, Used during Crystals forming phase during Supersaturated Cooling Heavy-duty, Slow Operation, 2 to 4 blades.

0 kommentar(er)

0 kommentar(er)